Efficient Production

Advanced Cutting Solution For Modern Industries

High-Precision Flatbed Cutting for Apparel, Footwear, Furniture, and Industrial Materials

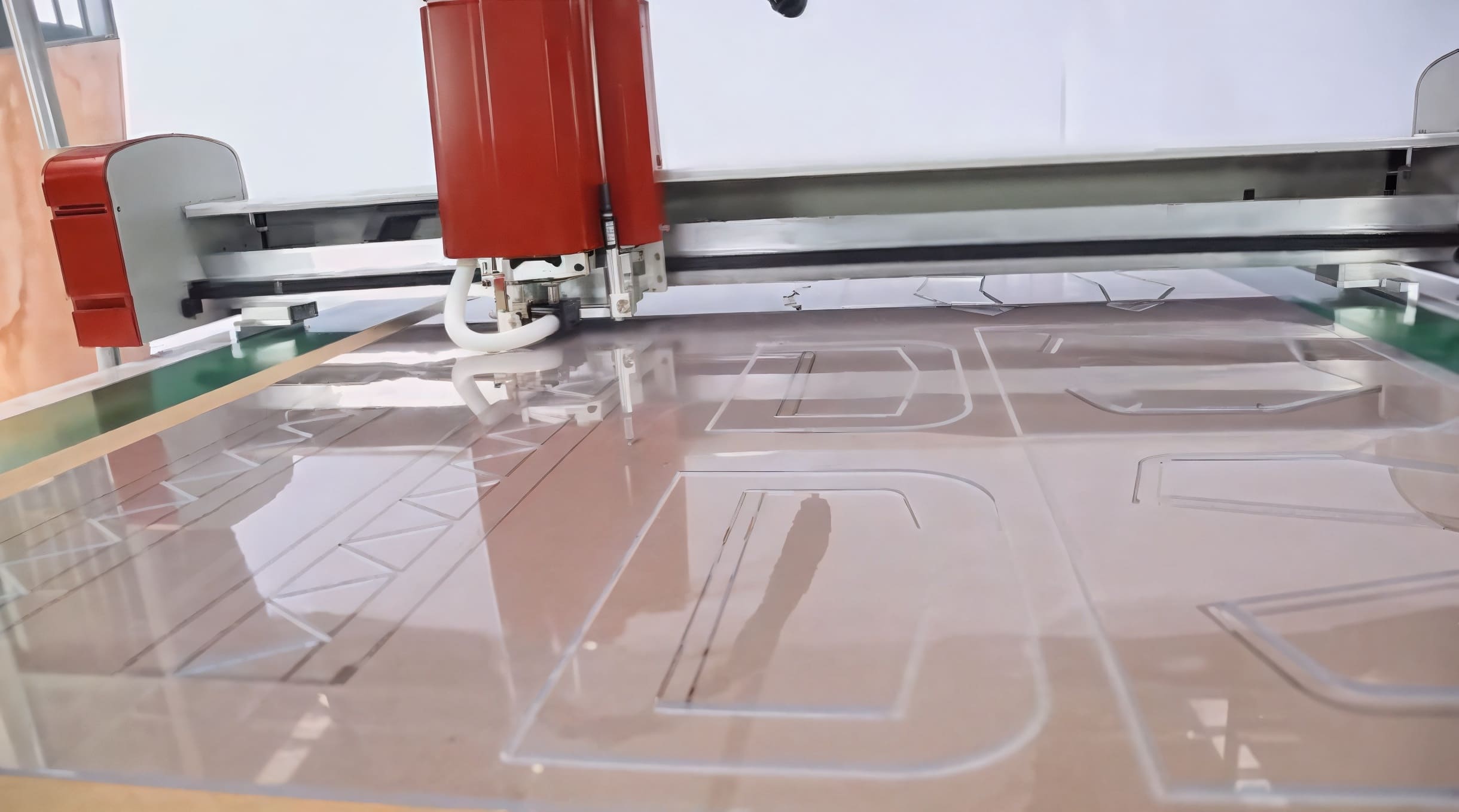

The Velocity Flatbed Cutter is a versatile, high-performance cutting system engineered to meet the rigorous demands of diverse industries, including garment manufacturing, footwear production, furniture design, and industrial textile fabrication. Built to deliver speed, accuracy, and durability, it transforms traditional workflows by enabling precise cutting, pattern marking, and scribing—all in one compact, efficient solution.

Whether you’re handling thick industrial materials or delicate design templates, the Velocity Flatbed Cutter optimizes productivity, reduces waste, and ensures exceptional repeatability—making it an indispensable tool for companies committed to innovation and quality.

A Complete Solution for Modern Cutting Challenges

Designed to go beyond basic cutting, the Velocity Flatbed Cutter supports complex workflows that involve plotting, annotation, scribing, and precision cutting. It seamlessly integrates with your existing CAD infrastructure and provides the flexibility needed to meet evolving production demands across a wide range of applications.

- Multifunctional Capabilities

- Plotting and Pattern Marking

- Precision Cutting and Die Cutting

- Clean Part Removal with dimensional Accuracy.

The system includes a specialized plotting and marking feature using a dedicated pen tool, allowing designers and operators to annotate patterns directly on material surfaces before cutting. This is especially valuable in industries like textiles, footwear, and furniture, where precise alignment of features and design elements is critical to the final product.

Advanced Cutting for Complex Materials

Engineered with a durable flatbed surface and a heavy-duty cutting blade, the Velocity Flatbed Cutter processes a wide variety of materials, including:

- Thick cardboard

- PVC sheets

- Rigid plastics

- Industrial textiles

- Paper, canvas, vinyl, and more.

Depending on your configuration, it can perform outer contour cuts, perforations, and die-cut-style incisions, making it ideal for applications such as folding, assembly, or prototyping.

After the cutting process, components are easily removed thanks to the system’s precision alignment and clean execution, ensuring parts match exact design specifications with no margin for error.

Key Features

Reinforced, Low-Friction Cutting Surface

The cutter’s specialized table surface reduces friction, improving material stability during operation and minimizing wear on blades—extending tool lifespan and reducing operational costs.

Universal Knife Design

With a high-tolerance hardened blade, the Velocity Flatbed Cutter handles both lightweight and dense materials using a single cutting head—eliminating the need for frequent tool changes and optimizing your workflow across varied production needs.

CAD and File Format Compatibility

Supports industry-standard formats including ISO, HPGL, HPGL2, and PLT, ensuring smooth integration with CAD software and design workflows. Load your files and start cutting with minimal configuration.

Modern Connectivity Options

Equipped with USB 2.0 and LAN ports for fast, stable data transfer and integration with both local and networked systems.

Flexible Cutting & Plotting Workflow

Print-Then-Cut Configuration

Easily configure your system to first annotate with vector lines, labels, or guides, then switch automatically to precise cutting along those paths. This guarantees alignment and registration accuracy.

Independent Annotation & Cutting Modes

If required, configure the system to only annotate internal pattern areas, followed by an external contour cut. This ensures maximum control at every stage of the process.

Sequential Operation (No Simultaneous Printing and Cutting)

The system performs one task at a time—either printing or cutting—to ensure maximum precision. Each operation is executed independently to avoid misalignment and ensure superior quality.

Available Sizes

The Velocity Flatbed Cutter is available in three standard work area configurations:

47″ x 35″

59″ x 35″

59″ x 47″

These formats offer versatility for both compact workshops and high-throughput production facilities, accommodating everything from intricate prototypes to full-scale production patterns.

Velocity Template Cutter Model

Industrial Power for Rigid Materials — Built for Professionals

The Velocity Template Cutter model brings enhanced power, speed, and durability to your cutting floor. Designed to tackle rigid materials like acrylic, PVC, and thick cardboard, this machine is ideal for professionals seeking high-precision, clean cuts in continuous production environments.

Plotting and Pattern Marking

Precise Cutting and Die Cutting

Part Removal and Precision Cutting Guarantee

The Flatbed Cutter not only performs precise cutting, but also offers the functionality of scribing and marking with a special marker. This is essential in the textile, footwear and furniture industries for drawing patterns, annotations and important features directly onto materials prior to cutting.

The system uses heavy-duty blades designed to handle wide variety of materials, such as thick cardboard, paper, PVC, rigid plastic and industrial textiles. Depending on the chosen configuration, the equipment can perform outer contour cutting or detailed perforations to simplify downstream processes like folding or assembly.

After completing the scribing and cutting process, the operator removes the parts with ease, thanks to the precision and efficiency of the Velocity Flatbed Cutter. Designed to deliver clean, accurate cuts, this machine ensures that each part meets the original design dimensions and specifications, with no deviations or imperfections.

Highlights & Advantages

Industrial-Grade Precision & Force

Perfect for processing hard substrates such as acrylic, PVC, and heavy cardboard.

24,000 RPM Milling Cutter

Delivers clean, accurate edges—even on the toughest materials.

Cutting Thickness Capacity

- 1–3mm for acrylic and PVC

- 0.1–1mm for kraft paper and cardboard

Reinforced Table with Vacuum Hold

Keeps materials firmly in place for smooth, error-free cuts.

Closed-Loop Servo System

Ensures precision and stability in continuous or complex operations.

Versatile and Energy-Efficient

Handles demanding details with professional accuracy—ideal for non-stop production with material flexibility.

Elevate Your Cutting Capabilities Today

Ready to reduce waste, improve precision, and accelerate your production? Discover how the Velocity’s Flatbed Cutters can revolutionize your operations—whether you’re cutting footwear patterns, rigid plastics, or industrial fabrics.

Request your personalized quote and explore tailored configurations that match your industry needs.

Get answers

Frequently Asked Questions

Does the plotter come assembled?

No, Velocity plotters are not pre-assembled due to shipping and logistical considerations.

However, we ensure that setup is fast, guided, and stress-free. Our technical team provides:

- Step-by-step remote installation support

- Configuration assistance for software and connectivity

- Calibration and first-run testing

- User training on operation and basic maintenance

Whether you’re local or remote, our priority is to ensure your plotter is fully operational from day one—with the guidance and support you need.

What type of ink does it use?

The plotter uses HP #45 black ink cartridges, which are widely available from retailers like Target, OfficeMax, Office Depot, and Amazon. You may also choose to purchase them through Velocity Plotters

What type of paper is recommended for the Flatbed Cutter?

- Pattern paper (Manila / Tag), Kraft / Brown paper, plotter paper, cardboard, PVC, and plastic board

- Recommended widths: 36″, 45″, 54″

- Core: 3-inch tube

- Grammage Manila / Tag: 100 WT – 120 WT – 150 WT refers to paper thickness

- Grammage Kraft / Brown: 40 WT – 50 WT refers to paper thickness